RobotLab LTH

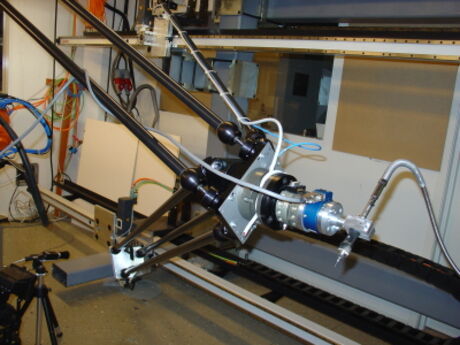

RobotLab LTH is an experimental arena shared by the Department of Automatic Control and the Department of Computer Science. Robotics is a multi-disciplinary topic, and we collaborate with both national and international robotics colleagues regarding different aspects of robotics and we also have a close cooperation with industrial partners. Our main research is in motion and compliance control, control system architectures and different sensor fusion problems with application mainly to industrial manipulators. We mainly use modified industrial robot control systems and UAVs as experimental platforms.

The purpose of past and present research projects is to show how to organize open robot control systems and to verify these ideas by means of experimental verification. As a part of this research, we have developed several experimental open robot control systems. The systems are built around industrially available robots that have been reconfigured for experimental purposes.

The developed specific robot interfaces and the integration of the robots into a complete system forms a unique environment for testing and development of algorithms for improvement of performance, sensor integration, programming automation and autonomous operation. New sensor interfaces with modification of hardware and realtime software architectures have been developed to accommodate the use of force control algorithms based on workspace sensing. The research in this area has been awarded with e.g., the EURON Technology Tranfer award and an ICRA Best Automation paper.

|  |

Ongoing projects:

- See RobotLab LTH homepage.

Some finished projects:

- Semantic Mapping and Visual Navigation for Smart Robots

- SelectiCa

- The Surgeon’s Perspective

- Autonomous Flight

- Innovative Construction with Flexible Robot-Human Interaction (Boverket)

- Innovative Agile Construction for Globally Improved Sustainability (ACon 4.0)

- Smart Assembly Robots with Advanced Functionalities

- SMErobotics - The European Robotics Initiative for Strengthening the Competitiveness of SMEs in Manufacturing by integrating aspects of cognitive systems (funding from European Union Seventh Framework Programme (FP7/2007-2013) under grant agreement n° 287787.)

- FlexiFab - Flexible fabrication of leightweight aluminum structures (EU FP7 under grant agreement no. FP7-SME-2014-2-606156-FLEXIFAB).

- ENGROSS - Enabling Growing Software Systems

- PRACE - The Productive Robot ApprentiCE (EU FP7)

- ROSETTA - RObot control for Skilled ExecuTion of Tasks in natural interaction with humans; based on Autonomy, cumulative knowledge and learning

- ProFlexA - Productive Flexible Automation

- COMET - Plug-and-produce COmponents and METhods for adaptive control of industrial robots enabling cost effective, high precision manufacturing in factories of the future (EU-FP7)

- SMErobot —The European Robot Initiative for Strengthening the Competitiveness of SMEs in Manufacturing (Integrated project funded under the European Union’s Sixth Framework Programme (FP6))

- SSF ProViking FlexAA

- Flexcon

- Autofett